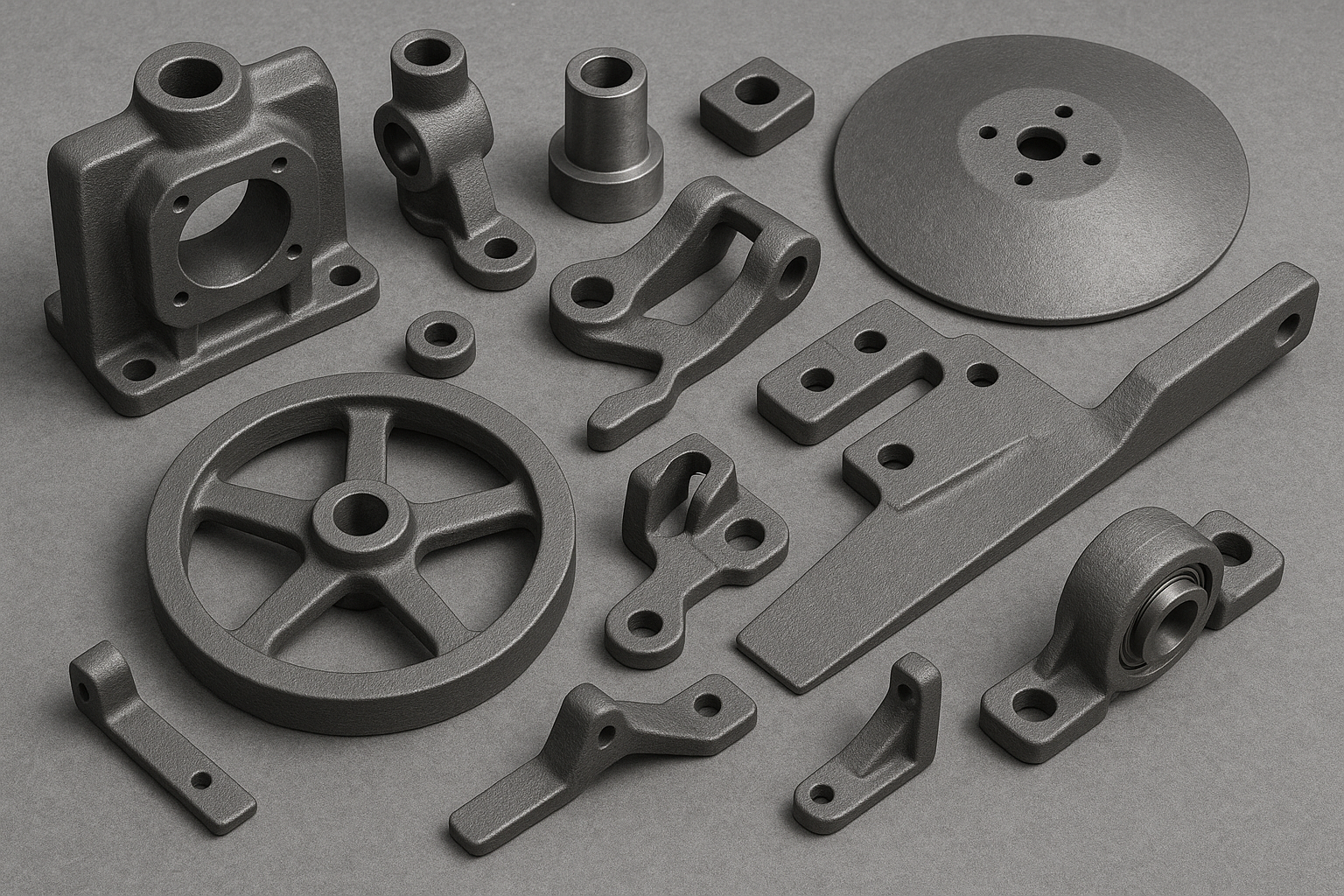

7 Powerful Cast Iron Parts for Agricultural Machinery You Need Today

Introduction

When it comes to powering modern farms, machinery plays a central role—but not just any machinery. What’s inside matters, and cast iron parts for agricultural machinery are the real MVPs behind those tractors, harvesters, and plows you rely on. Known for their unbeatable strength and durability, these parts keep your machines running through mud, heat, impact, and long hours in the field.

In this post, we spotlight 7 of the most powerful and essential cast iron components every agricultural machine needs. Whether you’re sourcing OEM agricultural castings, upgrading old equipment, or just looking to boost efficiency, these iron-clad heroes are your answer.

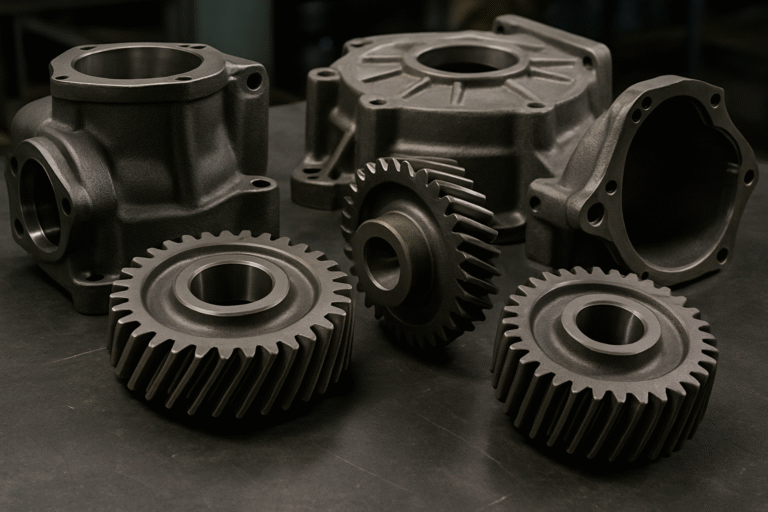

1. Gearbox Housings: The Power Protectors

The gearbox housing may seem like just a shell, but it’s one of the most critical parts in farm machinery. Made from ductile iron, it shields gears from dirt, moisture, and impact while maintaining alignment and load stability.

Why It Matters:

Withstands constant torque and vibration

Precision fit for OEM transmission systems

Enhanced with green sand casting for complex forms

2. Flywheels: Balancing Strength and Speed

In tractors and combines, flywheels regulate engine speed and reduce vibration. Cast iron flywheels are valued for their mass, balance, and ability to store rotational energy efficiently.

Benefits:

Smoothens power output in combustion engines

High thermal conductivity and damping properties

Long lifespan with minimal maintenance

3. Plowshares and Tiller Blades: Earth-Tough Champions

Few parts take as much abuse as plowshares. These parts are forged using heavy-duty agriculture castings, often from heat-treated gray or ductile iron to resist wear.

Ideal For:

Soil contact applications

Hard or rocky farming environments

OEM replacement for specialized tillers and plows

4. Clevis and Hitch Components: Secure and Steady Connections

Used to connect tools and trailers, cast iron clevises and hitches bear the brunt of field transport. They need to be reliable and ISO-certified to ensure safety in motion.

Highlights:

Excellent shock absorption

Manufactured using green sand casting for fast, custom shapes

Export-ready with consistent global standards

5. Bearing Housings and Wheel Hubs: Where Motion Meets Endurance

These castings ensure smooth wheel and axle performance. With precision iron casting parts, any failure in alignment or rotation is minimized.

Standout Features:

Reinforced for rugged terrain

High dimensional accuracy for OEM compatibility

Perfect for planters, harvesters, and wagons

6. Engine Mounts and Covers: Heat-Defying Shields

These parts must resist extreme heat, friction, and vibration. ISO-certified iron parts in this category help extend engine life and prevent costly repairs.

Benefits:

Excellent heat retention and distribution

Often combined with CNC finishing for perfect fitting

Essential for any high-performance agricultural engine

7. Custom Brackets and Supports: The Silent Workhorses

These support structures hold everything together. From dashboard panels to fluid containers, custom iron parts export services can produce these brackets in bulk or tailored formats.

Why Choose Custom:

Matches unique machine designs

Lowers manufacturing cost through bulk casting

Enhances overall structural integrity

Green Sand Casting: The Process Behind the Parts

Green sand casting is a leading technique used to manufacture many of these components. It’s favored for its:

Reusability and environmental safety

Capability for intricate mold designs

Cost-effectiveness for high-volume production

This process makes producing precision iron casting parts both practical and scalable.

Why OEM Agricultural Castings Matter

OEM parts ensure compatibility, performance, and long-term reliability. Whether you’re producing new tractors or repairing older models, working with OEMs:

Guarantees dimensional accuracy

Reduces risk of field failure

Enhances resale value and serviceability

How to Spot ISO-Certified Iron Parts

Always look for certification marks like:

ISO 9001 (Quality)

ISO 14001 (Environment)

ISO/TS 16949 (Automotive/manufacturing quality)

These certifications are critical when buying export-ready cast iron components for regulated markets like Europe and North America.

FAQs

1. Which cast iron part wears out fastest in farm equipment?

Plowshares and tiller blades wear out quickly due to constant soil contact and abrasion.

2. What makes ductile iron better than gray iron?

Ductile iron is more flexible and stronger, making it ideal for parts that endure stress or movement.

3. Are all green sand castings eco-friendly?

Yes, green sand casting uses natural materials like clay and sand, which are reusable and environmentally friendly.

4. Why should I choose OEM agricultural castings?

They ensure perfect fit, long-term reliability, and often come with performance guarantees.

5. Can cast iron components be exported globally without modifications?

Yes, as long as they are ISO-certified and comply with international dimensional and material standards.

6. How do I verify if a part is precision cast?

Ask for technical drawings, tolerances, and surface finish specs from your supplier.

Conclusion

Whether you’re an equipment manufacturer, farm operator, or industrial buyer, investing in the right cast iron parts for agricultural machinery can make a world of difference. These 7 powerful components are built to endure the toughest environments and improve the performance, safety, and efficiency of your machines. Don’t settle for average—choose precision, durability, and certified quality today.

1 Yorum

Wishing you happiness every day.